Ever wondered how often you need to put your electrical equipment through the wringer of testing and tagging? Well, strap in, because we’re about to dive into the electrifying world of rules and regulations that govern this process.

So, picture this: you’ve got a room full of electrical gadgets and gizmos, all waiting to be tested and tagged. But how often should you really be doing this? Well, my friend, the answer lies in a myriad of factors that can zap your equipment if you’re not careful.

From the type of equipment you’re dealing with to the environment it’s in, there’s a whole bunch of things that can influence the frequency of testing and tagging. But fear not, because we’re here to illuminate this electrifying topic and make it shockingly easy to understand.

So, get ready to charge up your knowledge and let’s get this party started!

Rules and Regulations for Testing and Tagging Electrical Equipment

You’ll love discovering the rules and regulations for testing and tagging electrical equipment. It’s like diving into a thrilling adventure filled with twists and turns, except instead of battling pirates or solving ancient riddles, you’ll be navigating the intricate world of electrical safety. So buckle up and get ready for a wild ride!

First things first, let’s talk about how often you need to test and tag your electrical equipment. The frequency of testing and tagging depends on the type of equipment and its usage. For example, portable electrical equipment used in a hostile environment, like a construction site, needs to be tested and tagged every three months. On the other hand, office equipment, like computers and printers, can be tested and tagged every five years. It’s like a game of ‘guess the frequency’- but don’t worry, we’ll guide you through it!

Now, picture this: you, armed with knowledge about the rules and regulations for testing and tagging electrical equipment, confidently striding through a room full of buzzing machinery like a superhero on a mission to save the day. You’ll be the talk of the town, the one who knows how to keep everyone safe from electrical hazards. So go ahead, embrace the adventure of testing and tagging, and let the rules and regulations be your trusty sidekick along the way!

Factors Influencing the Frequency of Testing and Tagging

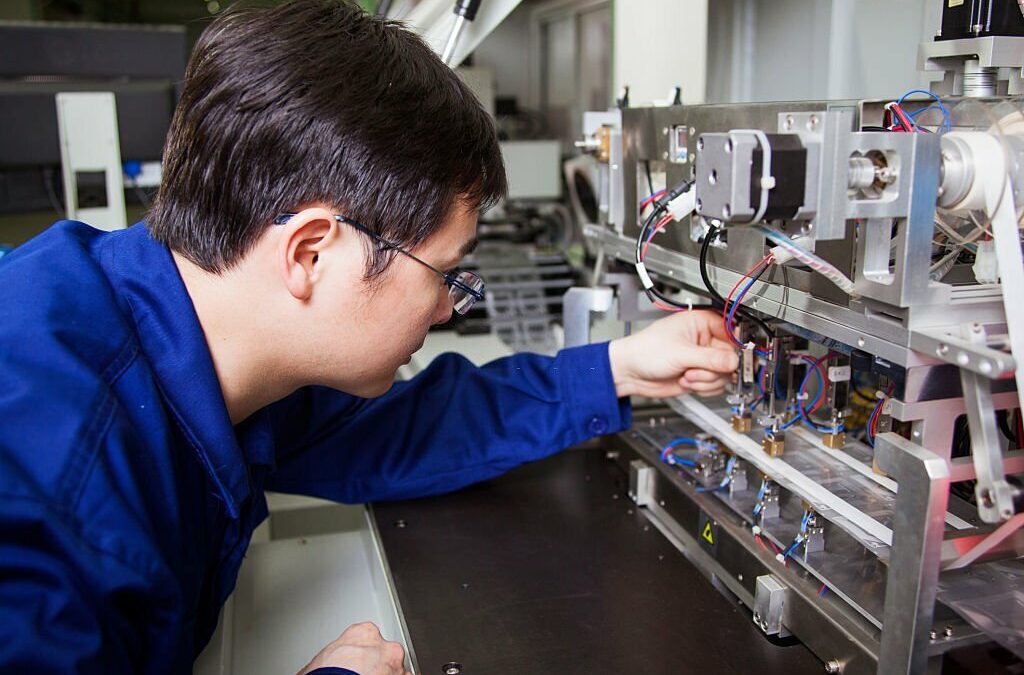

Regularly monitoring and assessing various factors can significantly influence how frequently you need to test and tag your electrical equipment.

One important factor to consider is the type of equipment being used. Some equipment, such as portable electrical tools that are subjected to rough handling or harsh environments, may require more frequent testing and tagging to ensure their safety. On the other hand, equipment that is rarely moved or used may not need to be tested and tagged as often.

Another factor to consider is the environment in which the equipment is being used. For example, if the equipment is used in a damp or dusty environment, it may require more frequent testing and tagging to prevent any potential hazards. Similarly, if the equipment is used in an area with high electrical loads or voltage fluctuations, it may need to be tested and tagged more frequently to ensure its continued safe operation.

Regularly monitoring and assessing factors like the type of equipment and the environment it is used in is crucial in determining how often you need to test and tag your electrical equipment. By staying proactive and ensuring regular testing and tagging, you can minimize the risks associated with faulty equipment and create a safer working environment.

So, don’t forget to keep an eye on these factors and keep your electrical equipment in tip-top shape!