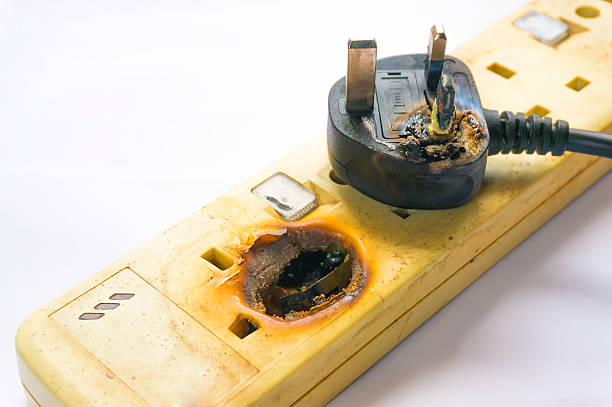

Are you tired of taking unnecessary risks with electrical equipment? Well, look no further than test and tag! This essential safety procedure ensures that your electrical appliances are in optimal condition, reducing the chances of electrical accidents or fires. Regular testing and tagging keep you safe and ensure compliance with safety regulations. You can prevent costly damages and possible injuries by identifying faulty equipment and addressing potential hazards. Don’t underestimate the power of test and tag – it’s a small investment that can make a big difference in your safety and peace of mind. So, why wait? Get your appliances tested and tagged today!

Importance of Test and Tag

Test and tag are important because it ensure your and your colleagues’ safety by identifying potential electrical hazards. Regularly testing and tagging electrical equipment can prevent accidents and injuries caused by faulty or unsafe equipment. When you use electrical appliances or tools in your workplace, there is always a risk of electrical shock, fire, or other accidents. However, implementing a test and tag program can minimize these risks and create a safer working environment for everyone.

Testing and tagging involves inspecting and testing electrical equipment to ensure it is safe. This includes checking for any damage, loose connections, or faulty components. Once the equipment passes the inspection, it is tagged with a label that indicates the date of the test and the next due date for retesting. This helps you track when each piece of equipment needs to be tested again.

By implementing a test and tag program, you can comply with safety regulations and standards, such as the Occupational Health and Safety Act. Regular testing and tagging also demonstrate your commitment to providing a safe workplace for your colleagues. It shows that you take their safety seriously and proactively prevent accidents and injuries.

Benefits of Regular Testing

Regular testing ensures your and your colleagues’ safety and identifies potential electrical hazards. By conducting regular testing, you can minimize the risk of electrical accidents and prevent possible injuries or even fatalities. One of the main benefits of regular testing is that it helps to identify any faults or defects in electrical equipment before they become a severe problem. This allows for timely repairs or replacements, reducing the chances of equipment failure and subsequent accidents. Additionally, regular testing ensures that your electrical equipment is working within the required safety standards. It helps to detect any deviations from these standards, such as insulation breakdown or faulty grounding, which can pose a severe risk to your safety.

Furthermore, regular testing helps to maintain compliance with legal and regulatory requirements. Many industries have specific regulations that mandate regular testing and tagging of electrical equipment. By adhering to these requirements, you not only ensure the safety of your workplace but also avoid potential legal consequences. Therefore, prioritize regular testing to safeguard yourself, your colleagues, and your workplace from electrical hazards.

Compliance With Safety Regulations

To ensure the safety of yourself, your colleagues, and your workplace, it is imperative to comply with safety regulations regarding the testing and tagging of electrical equipment. These regulations are in place to prevent electrical accidents, fires, and fatalities and to promote a safe working environment.

In many countries, including Australia, New Zealand, and the United Kingdom, some specific laws and regulations require regular testing and tagging of electrical equipment. These regulations outline the necessary steps and intervals for testing and the requirements for tagging equipment that has passed the testing.

By complying with these safety regulations, you can significantly reduce the risk of electrical accidents and ensure the safe functioning of your workplace. Regular testing and tagging help identify faults or defects in electrical equipment that may pose a safety hazard. This allows for timely repairs or replacements, preventing potential accidents.

Furthermore, compliance with safety regulations demonstrates your commitment to the well-being of your employees and the public. It shows that you prioritize safety and take the necessary precautions to protect everyone in your workplace.